Road Surfacing

Tarmacadam or Tarmac is often thought to be the cheapest method of road surfacing a driveway or forecourt, but for smaller areas it can work out quite expensive, and the red tarmacadam can be more expensive than block paving. Tarmacadam road surfacing has become a popular, although technically incorrect, term for both bitmac and for asphalt used to surface pavements, motorways and even internal floors.

Tarmac Surfacing can also be laid rather quickly which allows for minimal disruption to public services and commuters. Our work is usually carried out during off peak hours to further reduce the inconvenience to road users.

Tarmac is suitable for areas to be trafficked by vehicles, such as drives and forecourts, and can be used for paths. The wearing/surface course (the uppermost surface) can be ‘coloured’ by using a coloured binder, often with coloured aggregates, or by incorporating coloured, coated chippings into a wearing course.

There are literally dozens of different types of ‘tarmacadam’. Different aggregates, different aggregate sizes, different binders, different binder colours, the list goes on and on and there is a whole branch of the construction industry devoted to the specification of the various materials and the development of new products.

The basic premise of a Tarmac or asphalt surface is that the material is laid while hot and viscous, levelled and compacted as quickly as possible, and then allowed to cool so that it ‘sets’ and each particle is bound to its neighbours.

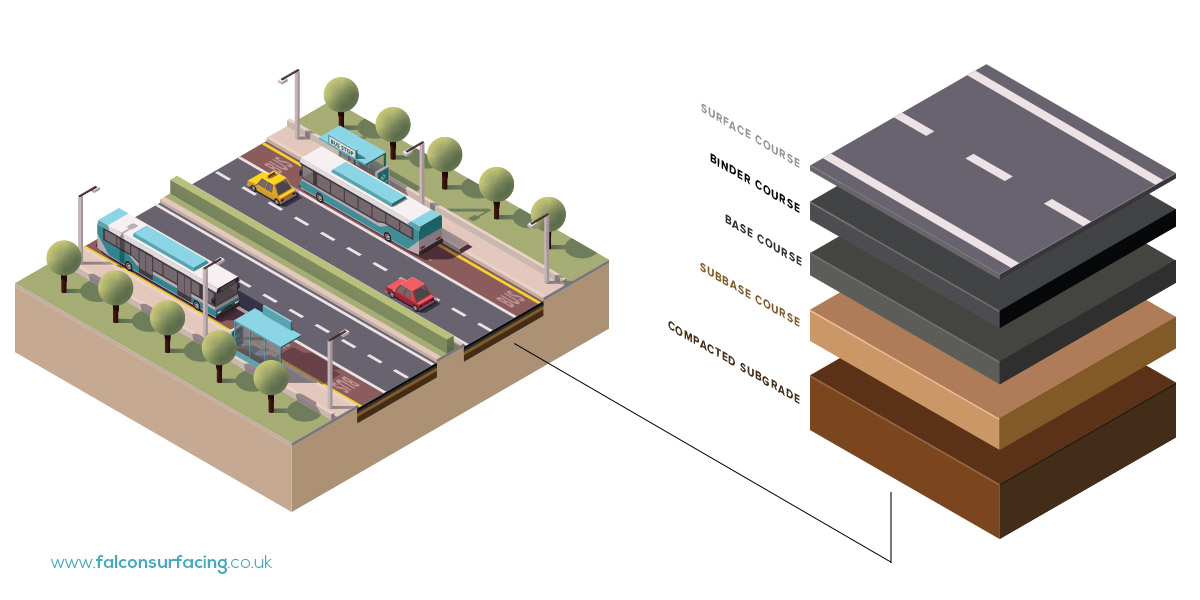

Bitmacs with large aggregates (up to around 70mm) are used as road bases or base/binder courses, and the smaller aggregates are used for the surface layer, more commonly known as the surface or wearing course. The general principle is that progressively smaller aggregates are used from the bottom of the pavement up towards the top, as this helps to spread the loads imposed upon the finished pavement by vehicles or other road users.